Yogo Sapphire Jewelry

Engagement RingsRings

Necklaces

Earrings

Bracelets

Vintage Jewelry

Men's Jewelry

All Yogo Jewelry

SHOP GEMSTONES

Shop Loose YogosLearn About Yogos

HistoryGemology

Uniquely Montana

Find Yogo Engagement RingsMontana Sapphire Jewelry

Engagement RingsRings

Necklaces

Earrings

Bracelets

Vintage Jewelry

Men's Jewelry

All MT Sapphire Jewelry

SHOP GEMSTONES

Shop Loose MT SapphiresLearn About Montana Sapphires

HistoryGemology

A True Treasure

Find Montana Sapphire Engagement Rings

Custom Jewelry

There are many

reasons to have a custom piece of jewelry made. You might have specific stones

that have strong sentiment that you want to frame in a unique setting. Perhaps

you know exactly what you want and just can’t find it anywhere. Or maybe you

love the style of one of our talented goldsmiths and designers and want to see

what they could come up with for you. Whichever the reason, our custom design

team is ready to get that project started.

Our in-house

designer and goldsmiths utilize a wide variety of processes and techniques to

design and create the jewelry of your dreams. Ranging from traditional hand

fabrication of sheet and wire to innovative uses of computer modeling and 3D

printing, we are well prepared to tackle even the most challenging designs.

Here’s a short

glimpse of what it takes to make a custom piece of jewelry as well as some of

the philosophies that guide our designing.

The Custom Process

Initial Idea

The process of creating your unique

jewelry begins by us learning about you. Our designers start by sitting down

with you to hear what is important to you. We not only want to make a piece

jewelry that you will love, but one that compliments and lives up to your

lifestyle.

Once our designers have a sense of

what you want, they use a variety of tools, such as hand sketching or

photorealistic computer renderings, to refine and communicate the design. We

use our experience to guide the technical design decisions, such as material

choices, stone setting styles and metal thickness, to create heirloom quality

jewelry.

Refined Design

Once an initial design has been approved, the next step

depends on which process will be used to create the final piece. Our three

primary methods of creating jewelry is traditional hand fabrication, hand

carving and casting wax, and CAD designing paired with 3D printing. Each

approach has its advantages, which our designers can help guide which process

is right for your design.

Cast pieces, whether hand carved or 3D printed all have a

modeling step. This is where all the final design elements come together. Often

you can see and try on the model to make certain all the details are exactly

what you want. Fabricated pieces are assembled from primitive components like

wire and sheet metal, so they often are built directly from a detailed drawing

or rendering.

Creating

After the model is finished and approved we use lost-wax

plaster casting to create a plaster form that we pour molten metal into to

create the piece. After the metal cools, our goldsmiths refine the metal form,

assemble any additional components and pre-polish.

Stone Setting & Project Completion!

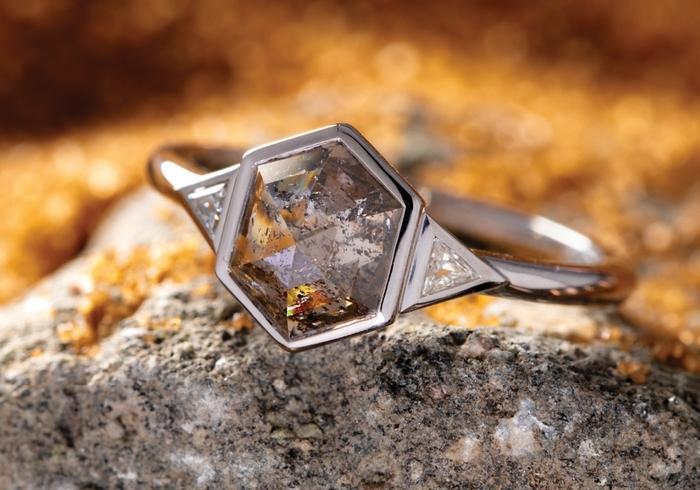

Now that we have the near finished body of your custom

designed piece, we finally get to the sparkly part of the process. Our

goldsmiths, under the magnification of our bench microscope, carefully carve

seats for the stones to sit in and then set the move metal to set the stones

tight and secure. Then our goldsmiths repolish the piece, smoothing out any

metal marked by the setting process, and give the piece its final polish. When

polishing and setting are complete, your one-of-a-kind piece is ready to begin

its life as a timeless treasure.

Featured Custom Jewelry Gallery

Request Custom Jewelry

What can we create for you?

* Required

Continue